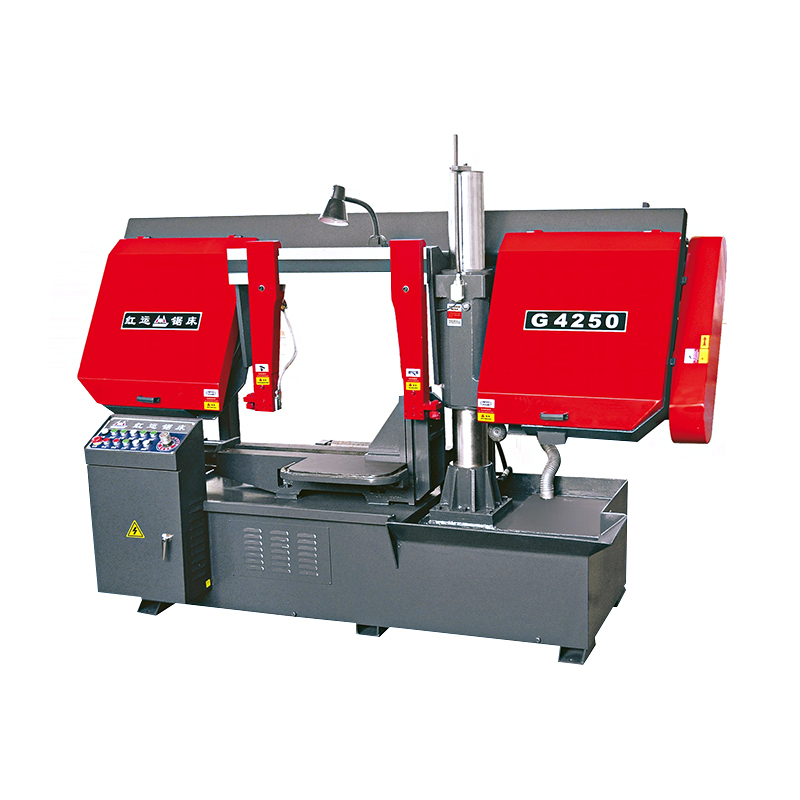

Some Reasons to Invest in a Horizontal Metal Bandsaw for Your Shop

The industrial sector is always on the lookout for tools that can streamline processes, increase productivity, and enhance the quality of their output. One such tool that has garnered significant attention in recent years is the horizontal metal bandsaw. This precision cutting machine is designed to handle a wide range of metal materials with ease and accuracy.

The horizontal metal bandsaw stands out for its ability to deliver clean, precise cuts across a variety of metal materials. This is particularly important in industries where precision is key, such as aerospace, automotive, and heavy machinery manufacturing. The horizontal bandsaw for metal is designed to minimize material waste and reduce operational costs, making it a smart choice for businesses looking to optimize their production processes.

One of the primary advantages of the horizontal bandsaw for metal is its versatility. Unlike traditional vertical bandsaws, horizontal metal bandsaws can handle a broader range of materials, including large and heavy pieces that would be challenging to maneuver in a vertical setup. This versatility allows for greater flexibility in the types of projects a shop can undertake, ultimately broadening the scope of work and increasing market opportunities.

Another compelling reason to invest in a horizontal metal bandsaw is the improved safety it offers. The horizontal orientation of the cutting action reduces the risk of accidents associated with flying debris, as the saw blades are contained within the machine's frame. This design feature not only protects workers from injury but also helps to maintain a clean and organized workshop environment.

Efficiency is another area where the horizontal bandsaw for metal excels. The cutting speed of these machines is often faster than that of their vertical counterparts, which means less downtime and quicker turnaround times for projects. This efficiency is particularly valuable in high-volume production environments where every minute saved can translate into significant cost savings.

Investing in a horizontal metal bandsaw also means embracing the latest technology in cutting tools. Many modern horizontal bandsaws come equipped with advanced features such as digital controls, which allow for precise adjustments to cutting speeds and blade tension. These features not only improve the accuracy of cuts but also extend the lifespan of the blades, reducing the need for frequent replacements and further cutting down on operational costs.

The horizontal bandsaw for metal also offers outstanding control over the cutting process. The horizontal orientation allows for better visibility of the cutting area, which is crucial for ensuring that cuts are made accurately and consistently. This is especially important in industries where precision is paramount, such as in the production of high-precision components for machinery or equipment.

When it comes to maintenance, horizontal metal bandsaws are generally easier to service than vertical bandsaws. The accessibility of the blade and other components means that routine maintenance and repairs can be performed more quickly and with less hassle. This not only reduces downtime but also minimizes the risk of costly repairs due to wear and tear.

In terms of space utilization, the horizontal bandsaw for metal is a more compact option compared to vertical bandsaws. This can be a significant advantage for shops with limited floor space, as it allows for the efficient use of available work areas without compromising on the capacity to handle large-scale projects.

The horizontal metal bandsaw is an environmentally friendly choice. By reducing material waste and optimizing cutting processes, these machines contribute to a smaller carbon footprint and align with the growing trend towards sustainable manufacturing practices.

The horizontal metal bandsaw is a powerful tool that offers numerous benefits for metalworking shops. Its versatility, safety, efficiency, technological advancements, control, maintenance ease, space-saving design, and environmental impact make it a worthwhile investment for businesses looking to stay competitive in today's fast-paced manufacturing landscape.

English

English 中文简体

中文简体 русский

русский