Horizontal Metal Saw Reduces Downtime In Cutting Processes

In modern manufacturing environments, efficiency and precision are crucial. One key factor in maintaining smooth operations is less downtime during metal cutting processes. A horizontal metal saw can play a significant role in achieving consistent performance and reducing operational interruptions. Among the various options, the Gantry Horizontal Metal Band Saw has gained attention for its ability to integrate into production lines while maintaining stable cutting operations.

Improving Workflow Consistency

Downtime in cutting processes can occur due to several factors, including blade wear, misalignment, and material handling issues. The Gantry Horizontal Metal Band Saw addresses these challenges through a robust design that supports consistent movement and precise blade tracking. With proper setup, a horizontal metal saw can reduce the frequency of stoppages, allowing operators to maintain a smoother workflow. In many industrial workshops, this has translated into measurable improvements in daily output without increasing labor intensity.

Versatility Across Materials

Another advantage of employing a horizontal metal saw is its versatility across different types of metals. From aluminum to steel, the Gantry Horizontal Metal Band Saw can handle a variety of thicknesses and profiles with small adjustment. This flexibility allows manufacturers to switch between projects more efficiently, further less downtime associated with tool changes or machine reconfiguration. Operators appreciate the ability to adapt cutting parameters quickly while maintaining consistent results.

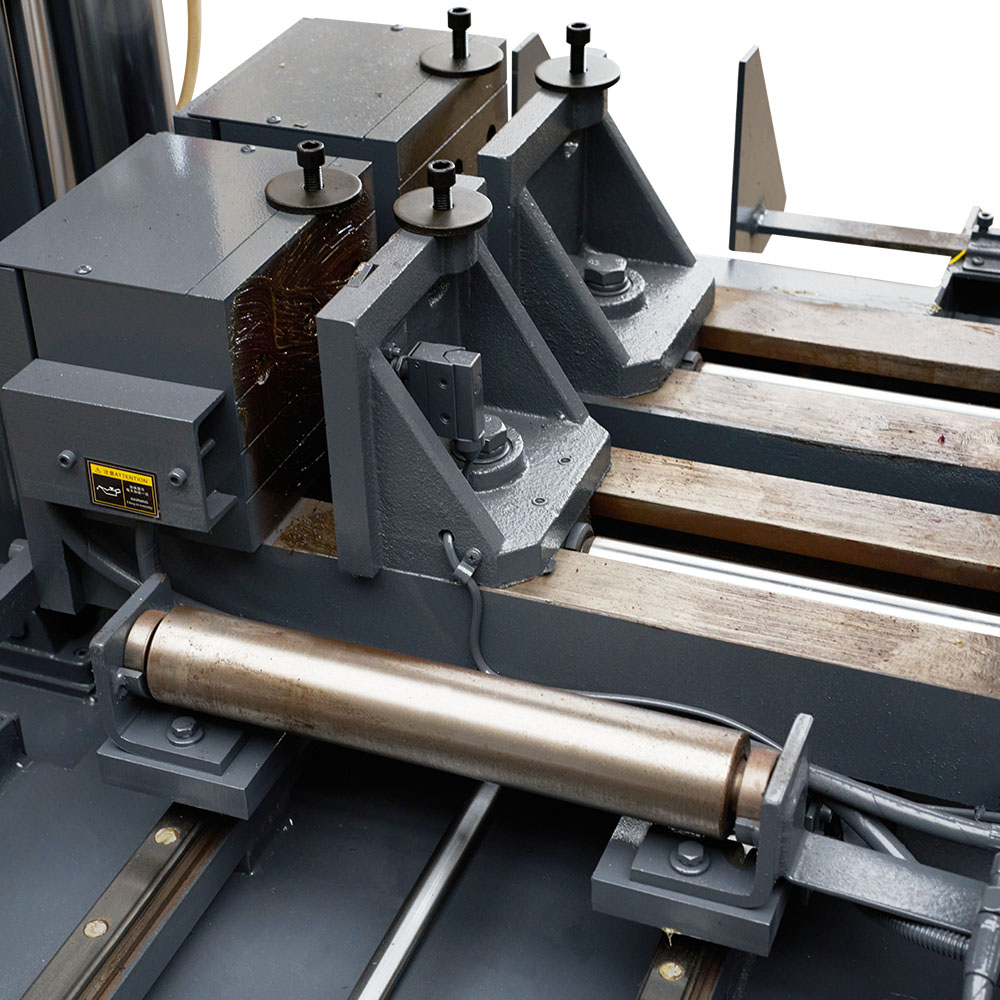

Maintenance and Reliability

Maintenance routines are also critical in reducing unplanned downtime. The Gantry Horizontal Metal Band Saw is designed with accessible components that simplify routine inspections and service. Regular lubrication, blade tension adjustments, and cleaning can be performed without significant disruption to production schedules. A horizontal metal saw with these design features helps facilities maintain continuous operation while avoiding prolonged interruptions that could affect deadlines.

Precision and Operational Stability

Precision in cutting is another factor that contributes to reduced downtime. Inconsistent cuts often require rework, which can delay downstream processes. By providing stable, accurate cuts, the Gantry Horizontal Metal Band Saw enhances overall production reliability. Coupled with the inherent stability of a horizontal metal saw setup, operators can achieve repeatable results that support predictable scheduling and less the need for corrective actions.

Integration in Modern Workshops

Many manufacturing facilities now focus on integrating machinery that aligns with automated or semi-automated workflows. The Gantry Horizontal Metal Band Saw, when used alongside other equipment, can contribute to a more synchronized production environment. Its ability to maintain steady operation over extended periods allows teams to plan cutting sequences efficiently and reduces the risk of unexpected stoppages. Similarly, horizontal metal saws provide a balance between capacity, precision, and maintainability that is suitable for a wide range of industrial applications.

Downtime during metal cutting processes is a challenge that can impact productivity and scheduling. Utilizing tools such as the Gantry Horizontal Metal Band Saw and horizontal metal saws, manufacturers can improve workflow consistency, handle diverse materials, simplify maintenance, and achieve precise cuts. By focusing on reliable machinery and thoughtful operational practices, facilities can maintain smoother production lines and reduce interruptions in their metalworking processes.

English

English 中文简体

中文简体 русский

русский