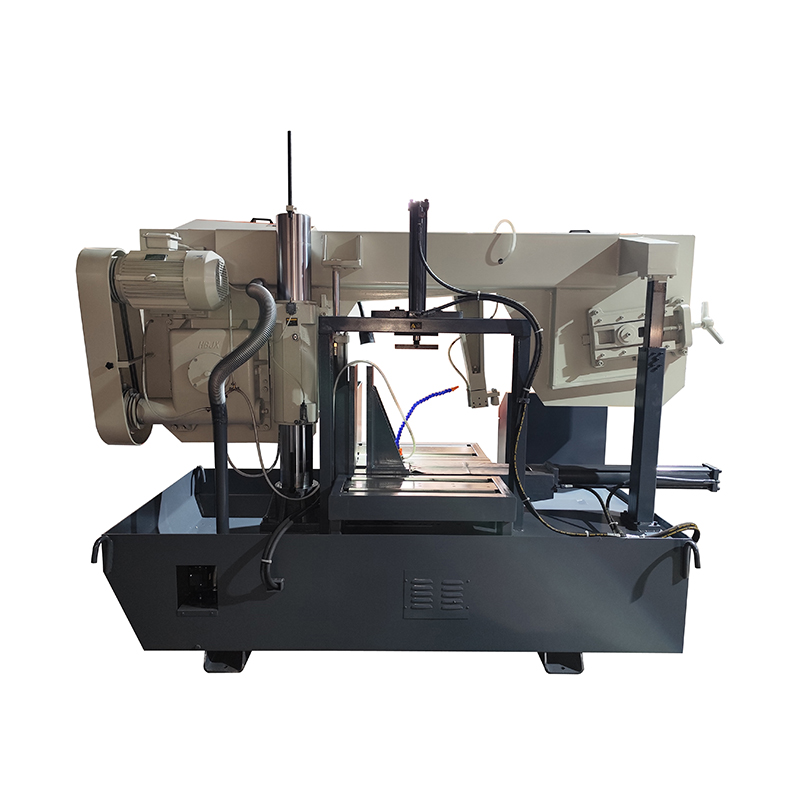

Gantry Horizontal Metal Band Saw Streamlines Production Workflows

In modern metalworking environments, efficient cutting processes are essential for maintaining consistent production schedules. The Gantry Horizontal Metal Band Saw has become a central tool in many workshops, providing a reliable means for handling various metal materials. Unlike traditional vertical saws, this horizontal design allows for greater stability during long cuts, ensuring that materials are processed with uniform accuracy. By integrating this type of saw into production lines, operators can achieve smoother workflows and reduce manual intervention.

Precision and Stability in Cutting

One of the key advantages of the Gantry Horizontal Metal Band Saw is its ability to maintain precision across different metal types and thicknesses. Horizontal metal saws are particularly useful when cutting large or heavy materials that might otherwise shift during processing. The gantry design adds structural support, which less vibration and contributes to consistent cut quality. In industries where tolerances are critical, such as construction or fabrication, this stability is essential for producing components that fit correctly and perform reliably.

Enhanced Workflow Integration

The integration of a Gantry Horizontal Metal Band Saw into a production workflow does not only impact cutting quality but also the overall efficiency of operations. Horizontal metal saws allow for automated feeding and clamping systems, which reduce the time operators spend repositioning materials. This streamlined process can decrease bottlenecks in a production line, making it easier for teams to maintain steady output without compromising on precision. Over time, the ability to handle larger batches without repeated adjustments improves both throughput and consistency.

Versatility Across Materials

Another notable aspect of the Gantry Horizontal Metal Band Saw is its versatility. Horizontal metal saws are capable of cutting a wide range of metals, from aluminum and copper to steel and alloys. This adaptability makes them valuable in workshops that handle diverse projects or produce custom components. Operators can adjust cutting speeds and feed rates to match material properties, ensuring that each cut is clean and accurate. The ability to accommodate different sizes and shapes of metal also reduces the need for multiple specialized saws, consolidating workflow efficiency.

Safety and Operational Considerations

Safety is a critical component of any metalworking environment. The Gantry Horizontal Metal Band Saw incorporates features that help reduce risks associated with high-speed cutting. Horizontal metal saws often include automatic shut-off mechanisms, protective guards, and clear operational interfaces to less the likelihood of accidents. By reducing the need for manual handling during cuts, these saws contribute to safer working conditions while maintaining consistent performance.

The Gantry Horizontal Metal Band Saw offers a combination of stability, precision, and versatility that can streamline production workflows. Horizontal metal saws allow operators to manage heavy or diverse materials efficiently, integrate smoothly into automated lines, and maintain consistent cutting quality. As metalworking demands continue to evolve, the implementation of such saws provides a practical solution for workshops aiming to balance productivity, safety, and precision without relying on bad performance claims. The Gantry Horizontal Metal Band Saw remains a valuable component in modern production environments, ensuring that materials are processed effectively while supporting reliable operational practices.

English

English 中文简体

中文简体 русский

русский