Double Column Horizontal Metal Band Saw vs. Double Column Sawing Machine: Key Considerations for Industrial Cutting

In the world of industrial metal cutting, double column horizontal metal band saws and double column sawing machines represent two of the most efficient solutions for heavy-duty applications. While these machines share some similarities, understanding their differences is crucial for manufacturers looking to optimize their cutting operations.

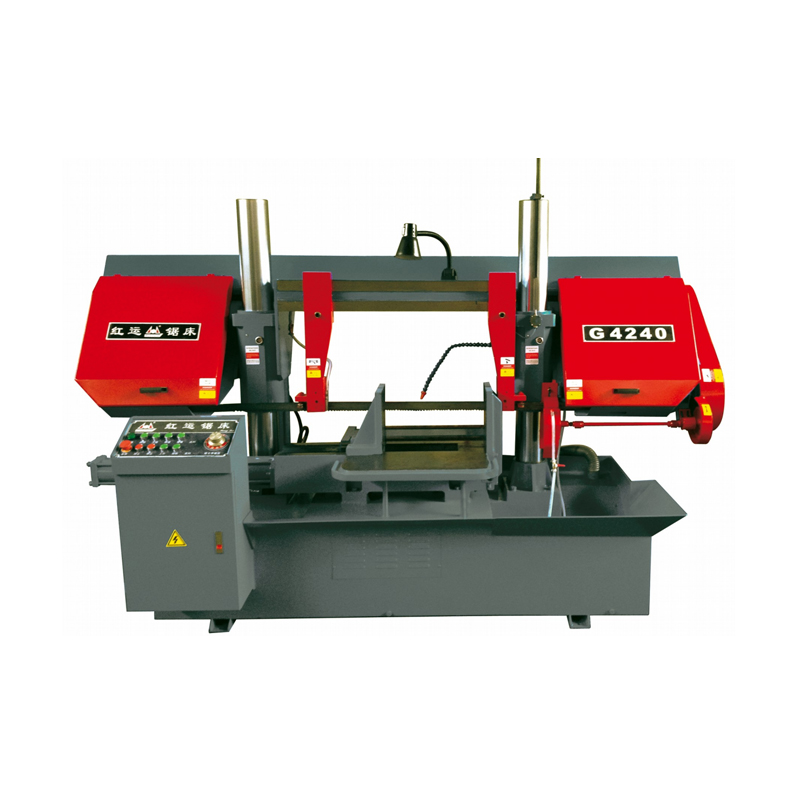

Structural Design and Stability

The double column horizontal metal band saw features a unique twin-column construction that provides exceptional stability during cutting operations. This design minimizes vibration, ensuring straight, precise cuts even when working with large, heavy materials. The horizontal orientation allows for easy material loading and unloading, particularly beneficial for long stock pieces.

Similarly, double column sawing machines utilize the same robust twin-column framework but often come in vertical configurations as well. The double column design in both machine types distributes cutting forces evenly, reducing wear on components and extending blade life. However, the double column horizontal metal band saw typically offers greater versatility in handling oversized workpieces due to its open cutting area.

Key advantages of both designs include:

- Enhanced rigidity for precision cutting

- Reduced maintenance requirements

- Improved operator safety

- Longer equipment lifespan

Cutting Performance and Efficiency

When comparing performance, double column horizontal metal band saws excel in continuous production environments. Their design allows for:

- Faster cutting speeds

- Automated material feeding systems

- Higher throughput for mass production

Double column sawing machines, on the other hand, often provide more flexibility in cutting angles and complex shapes. Many models feature CNC controls that enable programmable cutting sequences, making them ideal for job shops with diverse requirements.

Both machine types offer:

- Consistent cutting accuracy (±0.1mm tolerance)

- Reduced material waste

- Energy-efficient operation

- Compatibility with various blade types

The choice between a double column horizontal metal band saw and a double column sawing machine often comes down to production volume versus cutting complexity.

Industry Applications and Material Handling

Double column horizontal metal band saws dominate in industries requiring high-volume straight cuts, such as:

- Structural steel fabrication

- Pipe and tube production

- Aluminum extrusion processing

Double column sawing machines find their niche in applications demanding greater versatility:

- Aerospace component manufacturing

- Automotive part production

- Heavy equipment fabrication

Material handling differs significantly between the two:

- The double column horizontal metal band saw typically incorporates conveyor systems for continuous processing

- Double column sawing machines often feature rotary tables or tilting mechanisms for angled cuts

For operations processing large-diameter materials (300mm+), the double column horizontal metal band saw usually provides better support and stability. However, when cutting complex profiles or performing multiple operations in one setup, the double column sawing machine may be preferable.

Making the Right Investment Decision

Choosing between a double column horizontal metal band saw and a double column sawing machine requires careful consideration of:

1. Production requirements - Volume, material types, and cut complexity

2. Floor space - Horizontal models typically require more length

3. Automation needs - Both can be automated but with different approaches

4. Budget considerations - Initial cost versus long-term ROI

Modern double column horizontal metal band saws now incorporate IoT capabilities for predictive maintenance, while advanced double column sawing machines offer AI-assisted cutting optimization. These technological advancements make both options smarter investments than ever before.

For operations focused on straight cuts of long materials, the double column horizontal metal band saw remains the undisputed champion. For shops needing multi-angle capabilities and programming flexibility, the double column sawing machine offers superior adaptability. Many manufacturers find that having both types in their facility provides the ultimate in cutting versatility.

English

English 中文简体

中文简体 русский

русский