CNC Sawing Machines Enhance Accuracy And Speed In Metal Fabrication

In metal fabrication, precision and speed are two vital components of efficient production. The introduction of the CNC Sawing Machine has significantly influenced how manufacturers approach metal cutting tasks. With programmed control and consistent operation, this type of equipment brings a structured rhythm to processes that previously relied heavily on manual adjustments. As production demands increase across fabrication shops and industrial workshops, the value of repeatable, accurate cutting becomes increasingly clear.

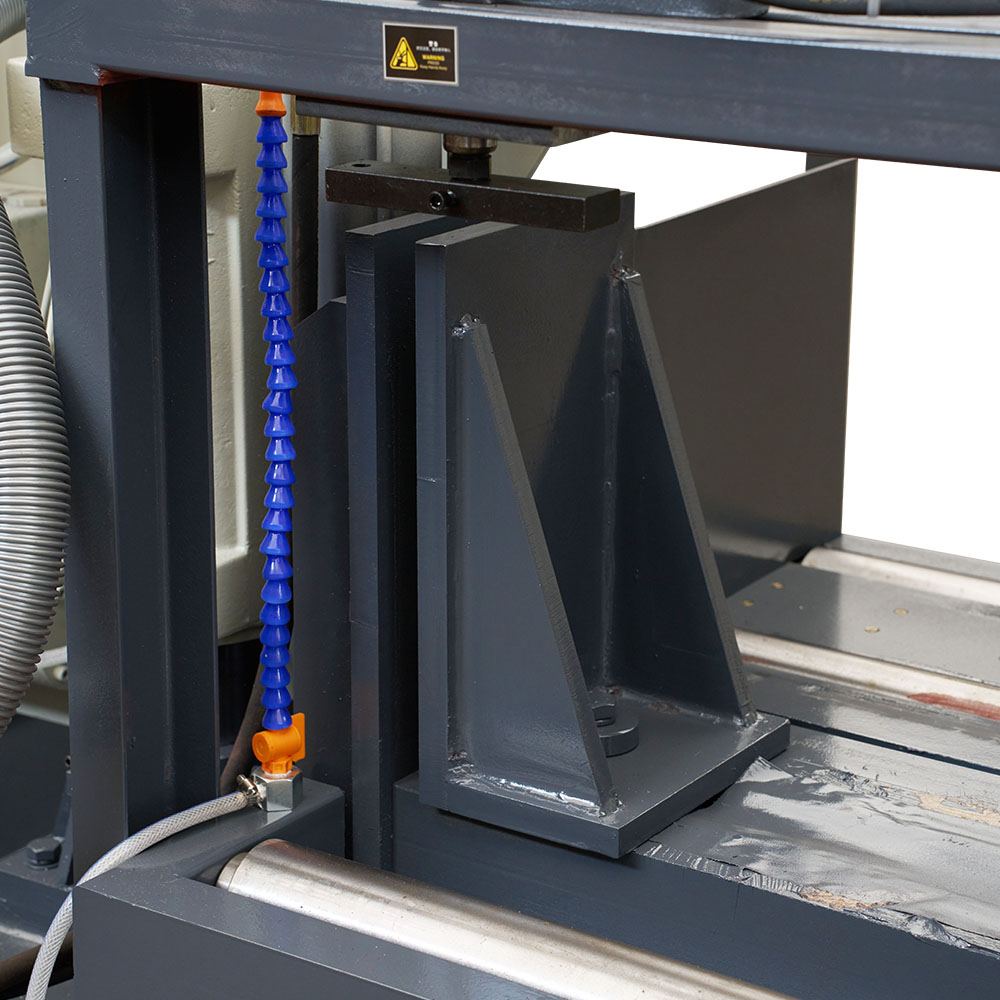

An automatic horizontal band saw plays a key role in supporting continuous workflows. Unlike manual or semi-automatic models, this saw operates with less supervision and can perform complex cuts with small deviation. It excels in handling bundles or long stock material, cutting them with consistent angles and feed rates. This makes the automatic horizontal band saw a practical choice for facilities managing high volumes or multiple shift operations.

The CNC Sawing Machine integrates numerical control with mechanical operation, allowing for precise measurements on every cut. Material waste is reduced as operators input detailed parameters into the system, which the machine follows closely without human error. In addition to reducing scrap, this consistency saves time typically spent on manual rework or recalibration. As a result, production cycles become shorter without sacrificing the final quality of the product.

When placed in a production line, the automatic horizontal band saw helps streamline batch processes. Whether cutting steel bars, aluminum profiles, or mixed alloy materials, its ability to deliver straight and even cuts contributes to better downstream performance. Welding, bending, or assembly tasks that follow benefit from the uniform pieces prepared by this saw type. These efficiencies contribute to improved coordination between teams within the same facility.

Many operations now use a combination of a CNC Sawing Machine and an automatic horizontal band saw to meet diverse project needs. While one handles programmed batch cuts, the other can be used for longer workpieces that require uniform slicing without complex setups. Together, they reduce operator fatigue and allow technical teams to focus on quality assurance and layout planning rather than repetitive cutting tasks.

A CNC Sawing Machine also supports integration with digital production environments. With the ability to import cut lists directly from CAD or ERP systems, these machines less input errors and eliminate manual data entry. This function promotes smooth transitions between design and fabrication stages. For businesses focusing on customization or working with varying cut lengths, this level of control adds flexibility without sacrificing pace.

The automatic horizontal band saw further complements digital workflows by maintaining reliable performance across material types and cutting conditions. From stainless steel rods to square tubing, this equipment delivers dependable results. Some models also include monitoring systems to track blade condition or coolant flow, helping reduce unexpected downtime.

Maintenance routines for both the CNC Sawing Machine and the automatic horizontal band saw are relatively straightforward, especially when preventive schedules are followed. Lubrication, blade checks, and alignment calibration ensure the systems continue operating efficiently. With proper care, these machines can support long-term use across various production schedules.

In summary, the combined use of a CNC Sawing Machine and an automatic horizontal band saw helps metal fabricators achieve greater precision and faster throughput. While each machine brings different capabilities, their contributions to modern fabrication environments are substantial. They support better resource use, more consistent results, and reduced manual labor, all of which contribute to a more effective production floor.

English

English 中文简体

中文简体 русский

русский