CNC Sawing Machine Technology Boosts Productivity In Industrial Operations

In today's competitive industrial landscape, the ability to cut materials with precision and speed is critical for maintaining efficiency. The CNC sawing machine has become an indispensable tool in various manufacturing sectors, transforming traditional cutting methods and enhancing operational capabilities. By integrating advanced computer numerical control (CNC) technology, manufacturers are now able to achieve highly accurate and repeatable cuts, drastically improving overall productivity.

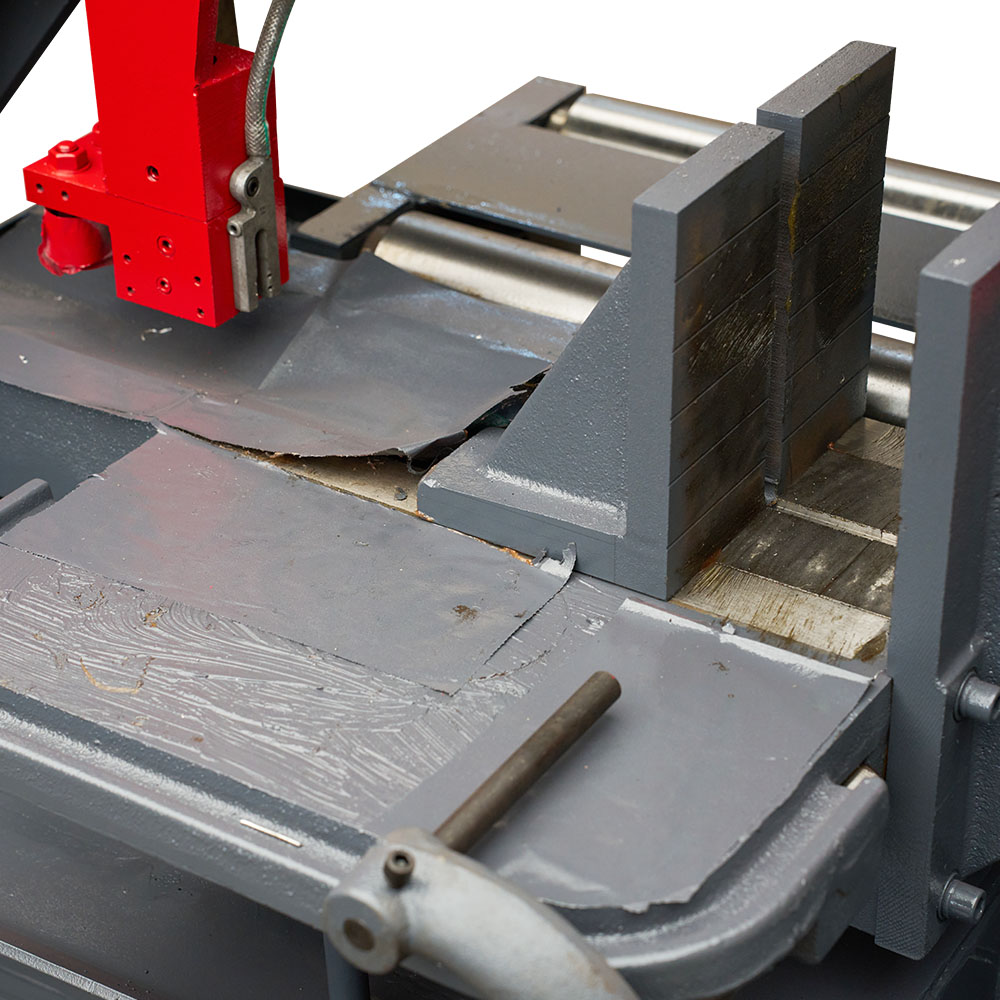

The automatic horizontal band saw plays a significant role in this transformation. Unlike manual sawing methods, which often involve time-consuming adjustments and inconsistent results, the automatic horizontal band saw offers consistent and reliable performance. This system can be programmed to cut multiple pieces of material with small human intervention, making it ideal for mass production environments where efficiency is paramount.

One of the standout features of the CNC sawing machine is its ability to make precise cuts on a variety of materials, including metals, plastics, and composites. With the ability to adjust settings such as cutting speed, blade tension, and feed rate, operators can tailor the machine to specific material types and thicknesses. This level of customization ensures that each piece is cut with high accuracy, which is essential for industries that require stringent tolerances, such as aerospace and automotive manufacturing.

Moreover, the automatic horizontal band saw enhances safety in the workplace. Traditional sawing methods often require workers to be in close proximity to the cutting zone, increasing the risk of accidents. With the CNC sawing machine system, however, the cutting process is automated, less the need for human intervention. This reduces the potential for injuries, allowing operators to focus on monitoring and overseeing the production process rather than handling the machine directly.

Efficiency is further amplified through the automatic horizontal band saw's ability to operate in continuous cycles. The machine can be set up to run for long periods without the need for constant supervision. This ability to cut uninterrupted increases throughput, making it an ideal solution for industries dealing with large volumes of material. Additionally, the CNC sawing machine reduces material waste by optimizing the cutting process, resulting in more parts being produced from the same amount of raw material. This waste reduction not only saves costs but also supports sustainability goals within manufacturing operations.

The integration of CNC sawing machine technology has also led to significant advancements in speed. Automated saws can complete cuts faster than manual methods, which helps meet tight production schedules. This reduction in cutting time directly contributes to the overall productivity of a facility, as it allows for more materials to be processed within a shorter time frame. As a result, manufacturers can increase their output without compromising on the quality of the cuts.

In addition to enhancing speed and precision, the automatic horizontal band saw can be programmed to cut multiple shapes and sizes, providing flexibility in production. This adaptability makes it a versatile tool in industries that require different cutting patterns for their products. The ability to quickly switch between various cutting styles without having to reconfigure the machine or adjust the setup is a significant time-saver, further boosting productivity.

The combination of speed, precision, and automation makes the CNC sawing machine an essential component of modern manufacturing operations. By adopting this advanced technology, manufacturers can not only improve efficiency and reduce costs but also ensure a higher level of consistency and safety in their processes. As industries continue to demand greater production rates and quality standards, the automatic horizontal band saw stands out as a crucial tool in achieving these goals.

In conclusion, the evolution of CNC sawing machine technology has brought about a revolution in how materials are processed in industrial settings. With the automatic horizontal band saw pilot the charge, manufacturers can now achieve exceptional levels of productivity, safety, and accuracy. As technology continues to evolve, we can expect even further improvements in these machines, making them an even more integral part of manufacturing success.

English

English 中文简体

中文简体 русский

русский